OUR CASTING COMPETENCES

Sand casting

Casting with sand core packages enables a high degree of design freedom. These are important especially for complex cast components and lightweight applications where additional functions are integrated. Sand casting is particularly suitable for cylinder crankcases and electric motor housings. It is also used in prototype production, small series and generally in development applications.

Component weight:from 10 to 60 kilograms

Component weight:from 10 to 60 kilograms

Low-pressure casting

Low-pressure casting is a homogeneous casting process for particularly high component strengths. As an integrated process, it is particularly suitable for the production of components with undercuts. Low-pressure casting is mainly used for medium quantities in permanent mould sand casting and for cylinder crankcases and chassis parts.

Weight: greater than 10 kilograms

Dimensions: up to 1000 mm x 500 mm

Weight: greater than 10 kilograms

Dimensions: up to 1000 mm x 500 mm

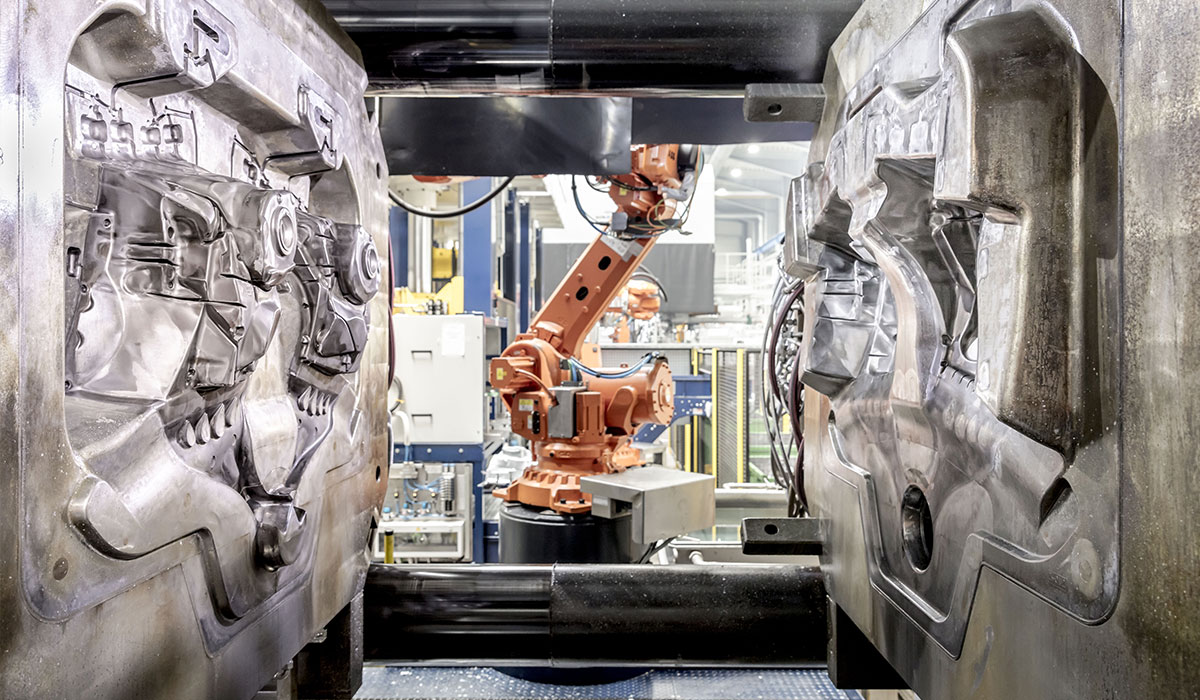

High-pressure casting

High pressure casting is efficient and cost-optimised and is particularly suitable for medium and high volumes of cylinder crankcases and structural components. Die casting is used to realise thin wall thicknesses and to produce very light components.

Clamping force: greater than 2500 tons

Weight: up to 30 kilograms

Clamping force: greater than 2500 tons

Weight: up to 30 kilograms

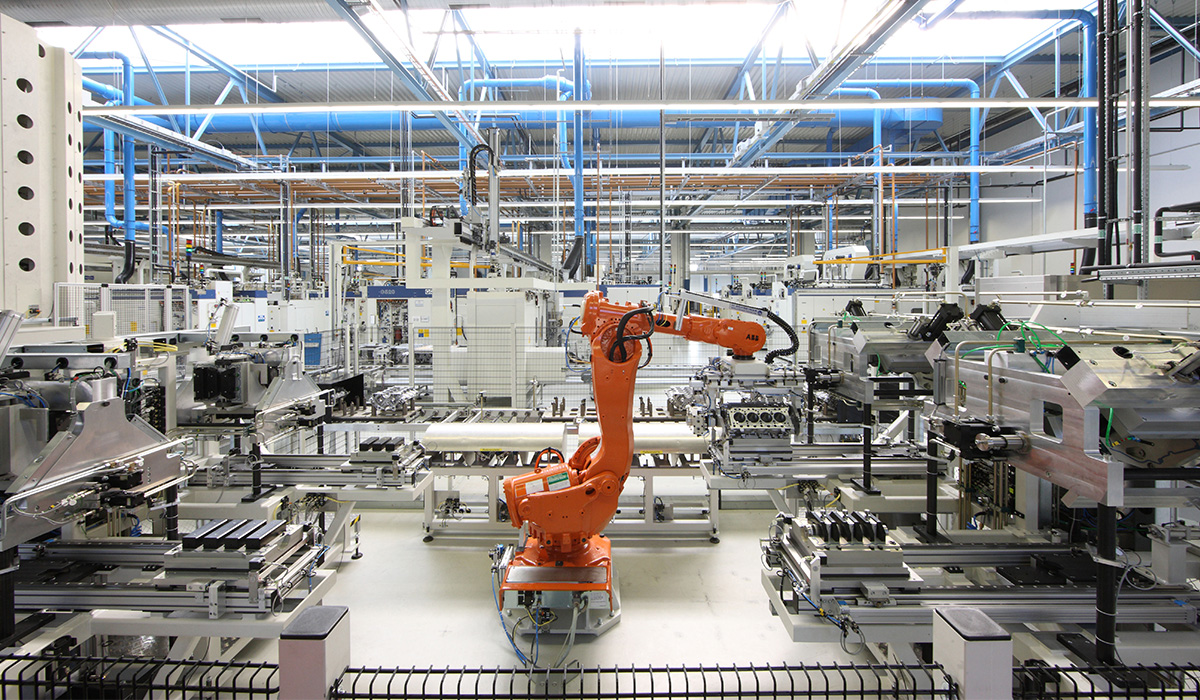

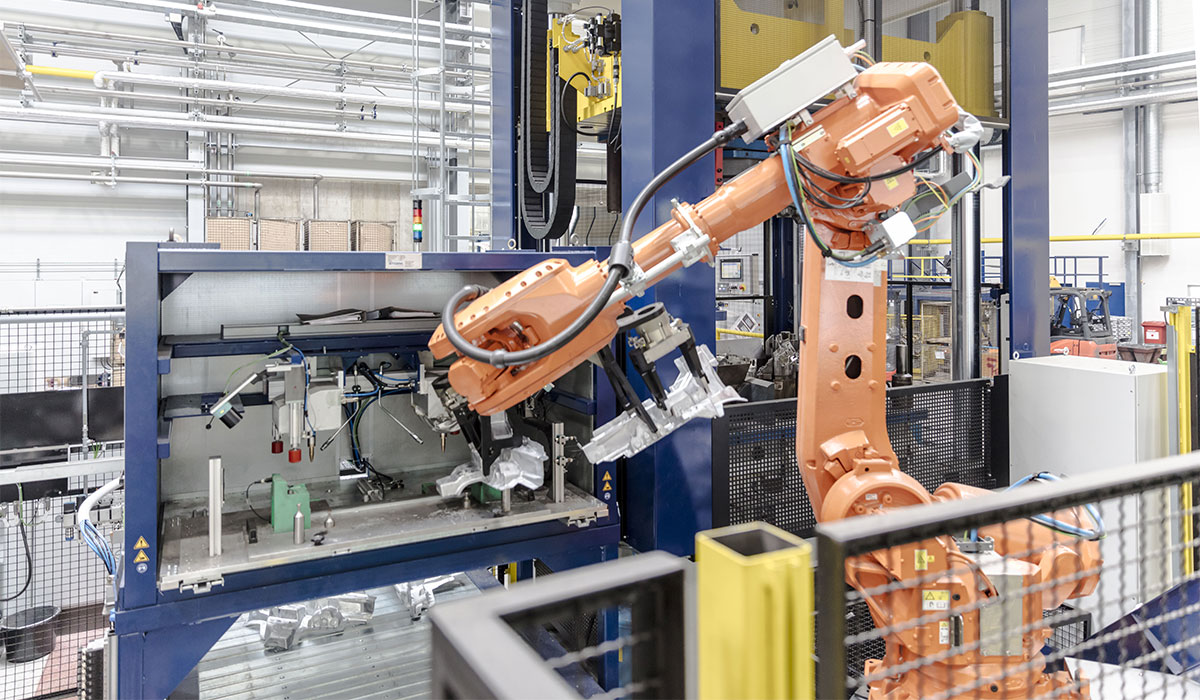

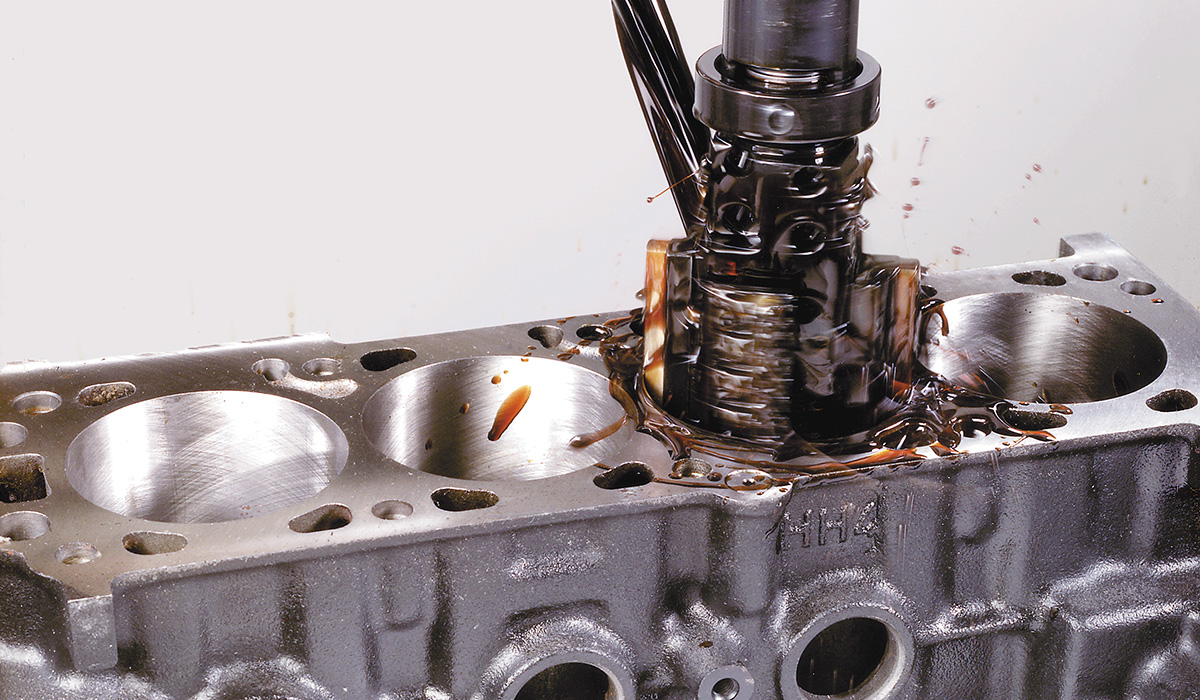

MACHINING

Global Castings offers its customers not only casting applications, but also their pre- and finish-machining under one roof.

This includes professional coating technologies, honing and assembly for small and large series and prototypes.

Classic applications are cylinder crankcases, structural components, chassis parts, e-mobility and non-automotive casting projects.

This includes professional coating technologies, honing and assembly for small and large series and prototypes.

Classic applications are cylinder crankcases, structural components, chassis parts, e-mobility and non-automotive casting projects.